Pressura plena iuncta Ball Valvae pro oleo & Gas

BAL702

Product Description

IFLOW pressionem altae valvulae pilae plene iunctae ad applicationes extrahentes sunt supremae solutiones pro industria olei et gasi. Artificium praecisionem machinalis et acumen technologiae adhibens, plectrum ordinatur ad extremas condiciones sustinere et singularem observantiam in ambitus contrahendi praebere. Construitur magna materiarum vis et corpus plene conflatum propter eximiam firmitatem et constantiam, id quod aptam facit ad littus operationum.

Valvula instructa est mechanismo signatorio provecta, quae strictam clausuram et minimam lacus efficit, eoque auget salutem et environmental tutelam officinarum littoris. Eius consilium asperum et magnae pressionis facultates aptas ad criticas applicationes efficiunt, inconsutilem fluxum imperium et optimalem observantiam sub condiciones pressionis altae praebentes. Constructio plene iuncta eliminat potentias fatiscere puncta, dans tibi pacem mentis et ad integritatem e regione olei et systematis gasi.

IFLOW scriptor summus pressurae valvulae pilae plene iunctae ordinantur ad industriam signa et regulatory requisita, obsequentia et fides in operationibus offshore praestandi. Eius consilium compactum et efficax lineamenta institutionis efficiunt solutionem sumptus efficacem et humilem sustentationem pro officinae littoris. Elige IFLOW scriptor summus pressurae valvulae pilae plene iunctae pro applicationibus extrahendi et experientiam qualitatem superiorem, durabilitatem et effectus in ambitibus contra ipsam maxime exigentibus.

Features

Product Overview

Circumscriptio machinari potest ad applicationem tuam accommodatam, cum constructione corporis, materia et notis ancillis optimized ad occurrendum processui tuo necessario. Cum ISO 9023 certificati sumus, vias systematicas adhibemus ut altam qualitatem obtineamus, certificari potes ex praestanti fidelitate et obsignatione observantia per consilium vitae tuae dignissim.

Technical opus est

· Operationis Impetus: PN20

· Opus Temperature: -10℃~170℃

· MEDIUM EXERCITATIO: Aqua, oleum et vapor

Specification

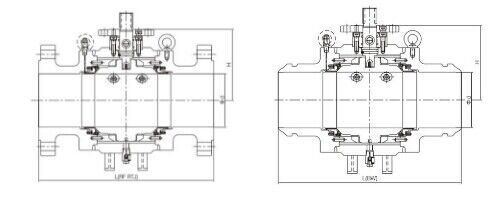

Product wireframe

Dimensiones Data

Specification

| Nominal diametri (in) | NPS6-40 | ||||||

| Pressura nominatim (Mpa) | Class150-Class900 | ||||||

| NO | PARS NAME | CARBON CHALYBEIUS | TACITURNITAS STELL | ||||

| Materia partium | 1 | Corpus | ASTMA105 | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L |

| 2 | Anti- ignis sarcina | Graphite | |||||

| 3 | Sedes | PTFE/NYLON/PEEK/PPL | |||||

| 4 | Sedes annulum | ASTM A105.ENP | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 5 | O inauris | VITON | |||||

| 6 | Ver | 17-7PH | |||||

| 7 | Bonnet | ASTMA105 | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 8 | Iniectio valvae sealant | partes deducta | partes deducta | partes deducta | partes deducta | partes deducta | |

| 9 | reprehendo valvae | partes deducta | partes deducta | partes deducta | partes deducta | partes deducta | |

| 10 | Ball | ASTM A105.ENP | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 11 | Mitte gasket | PTFE | |||||

| 12 | illapsum afferentem | Metallum+PTFE | Metallum+PTFE | Metallum+PTFE | Metallum+PTFE | Metallum+PTFE | |

| 13 | Pin | ANSI 1035 | ANSI 1035 | ANSI 1035 | ANSI 1035 | ANSI 1035 | |

| 14 | Ferens possessor | ASTM A105.ENP | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 15 | Sigillum glandulae | ASTM A105.ENP | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 16 | Mitte afferentem | PTFE | |||||

| 17 | Stem | ASTM A 182 F6a | ASTM A182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 18 | Flat key | ANSI 1045 | ANSI 1045 | ANSI 1045 | ANSI 1045 | ANSI 1045 | |

| 19 | Mitte afferentem | PTFE | |||||

| 20 | Anti-ignis gasket | SST+Graphite | |||||

| 21 | Connection laminam | ASTMA105 | ASTMA182 304 | ASTMA182 316 | ASTMA182 304L | ASTM A182 316L | |

| 22 | Caput tabernaculi cap cochlea | A193 B7M | A320 B8 | A320 B8M | A320 B8 | A320 B8M | |

| 23 | stipare | Graphite | |||||

| 24 | Stipare glandulae | ASTM A 182 F6a | ASTM A 182 F6a | ASTM A 182 F6a | ASTM A 182 F6a | ASTM A 182 F6a | |

| 25 | Anti-static valvae | partes deducta | partes deducta | partes deducta | partes deducta | partes deducta | |

| 26 | Air release valvae | partes deducta | partes deducta | partes deducta | partes deducta | partes deducta | |

| 27 | INCILE valvae | partes deducta | partes deducta | partes deducta | partes deducta | partes deducta | |

| Applicalbe condiciones muneris | Lorem media | Aqua vapor, oleum, gas, liquefactum, gas, gas naturale, etc | Acidum nitricum acidAceticum | Acidum aceticum | Fortis Oxidizer | Urea | |

| Applicabe temperatus | 120℃(PTFE).≤80℃(NYLON),≤250℃(PEEK), ≤250℃(PPL) | ||||||

| Design and vestibulum | API 608, API6D | ||||||

| Facie ad faciem dimensiones | ASME B16.10, API 6D,JIS B2002 | ||||||

| Genus connexionis | Flange | ASME B16.5/ASME B16.47 | Bult glutino | ASME B16.25 | |||

| Pressura test | API598. API6D | ||||||

| Modus tradendi | Calces manualis, vermis et vermis tradenda, pneumatica, electric | ||||||

Dimensiones datae (mm)

| Pressura rating | Nominal Diameter | d | Flange | Bult glutino | H | Pondus (kg) | |||

| Classis | NPS | DN | L(RF) | L(RTJ) | L(BW) | WE | RF | ||

| 150 | 6″ | 150 | 150 | 394 | 406 | 457 | 225 | 185 | 220 |

| 8″ | 200 | 201 | 457 | 470 | 521 | 258 | 250 | 290 | |

| 10″ | 250 | 252 | 533 | 546 | 559 | 310 | 400 | 430 | |

| 12″ | 300 | 303 | 610 | 622 | 635 | 350 | 550 | 620 | |

| 14″ | 350 | 334 | 686 | 699 | 762 | 382 | 820 | 900 | |

| 16″ | 400 | 385 | 762 | 775 | 838 | 421 | 1100 | 1220 | |

| 18″ | 450 | 436 | 864 | 876 | 914 | 468 | 1400 | 1550 | |

| 20″ | 500 | 487 | 914 | 927 | 991 | 510 | 1750 | 1950 | |

| 24″ | 600 | 589 | 1067 | 1080 | 1143 | 592 | 2800 | 3050 | |

| 26″ | 650 | 633 | 1143 | . | 1245 | 635 | 2900 | 3250 | |

| 28″ | 700 | 684 | 1245 | . | 1346 | 675 | 3400 | 3700 | |

| 30″ | 750 | 735 | 1295 | . | 1387 | 723 | 4800 | 5300 | |

| 32″ | 800 | 779 | 1372 | . | 1524 | 751 | 5500 | 6000 | |

| 36″ | 900 | 874 | 1524 | . | 1727 | 858 | 7550 | 8370 | |

| 40″ | 1000 | 976 | 1753 | . | 1956 | 930 | 10290 | 11320 | |

| 300 | 6″ | 150 | 150 | 403 | 419 | 457 | 225 | 185 | 230 |

| 8″ | 200 | 201 | 502 | 518 | 521 | 258 | 250 | 300 | |

| 10″ | 250 | 252 | 568 | 584 | 559 | 310 | 400 | 460 | |

| 12″ | 300 | 303 | 648 | 664 | 635 | 350 | 550 | 670 | |

| 14″ | 350 | 334 | 762 | 778 | 762 | 382 | 820 | 1000 | |

| 16″ | 400 | 385 | 838 | 854 | 838 | 421 | 1100 | 1320 | |

| 18″ | 450 | 436 | 914 | 930 | 914 | 468 | 1400 | 1650 | |

| 20″ | 500 | 487 | 991 | 1010 | 991 | 510 | 1750 | 2000 | |

| 24″ | 600 | 589 | 1143 | 1165 | 1143 | 592 | 2800 | 2550 | |

| 26″ | 650 | 633 | 1245 | . | 1245 | 635 | 2900 | 3300 | |

| 28″ | 700 | 684 | 1346 | . | 1346 | 675 | 3400 | 3750 | |

| 30″ | 750 | 735 | 1397 | . | 1397 | 723 | 4800 | 5500 | |

| 32″ | 800 | 779 | 1524 | . | 1524 | 751 | 5500 | 6500 | |

| 36″ | 900 | 874 | 1727 | . | 1727 | 858 | 7550 | 8800 | |

| 40″ | 1000 | 976 | 1956 | . | 1956 | 930 | 10290 | 1900 | |

| Pressura rating | Nominal Diameter | d | Flange | Bult glutino | General | Pondus (kg) | |||

| Classis | NPS | DN | L(RF) | L(RTJ) | L(BW) | H | WE | RF | |

| 600 | 6″ | 150 | 150 | 559 | 562 | 559 | 255 | 250 | 330 |

| 8″ | 200 | 201 | 660 | 664 | 660 | 290 | 340 | 450 | |

| 10″ | 250 | 252 | 787 | 791 | 787 | 320 | 570 | 710 | |

| 12″ | 300 | 303 | 838 | 841 | 838 | 380 | 580 | 1000 | |

| 14″ | 350 | 334 | 889 | 892 | 889 | 410 | 1100 | 1370 | |

| 16″ | 400 | 385 | 991 | 994 | 991 | 435 | 1350 | 1650 | |